The Mediterranean Diet: Delicious and Healthy

We cook with extra virgin olive oil! We have found that olive oil is at its best in simple dishes

The bag-in-box (abbreviated as BiB) has been known as a packaging concept for a long time. The packaging consists of a cardboard box with an inner bag or tube that is fitted with a tap. In the 1980s, the bag-in-box was first offered for fruit juices or wine. The bad image of the BiB also comes from this time, because many consumers suspect inferior mass products in it, and thus still see it as an indication of low quality. Some consumers are therefore also skeptical about olive oil in a bag-in-box. This is a pity, because in terms of both the shelf life of the olive oil and sustainability, there is hardly a better alternative.

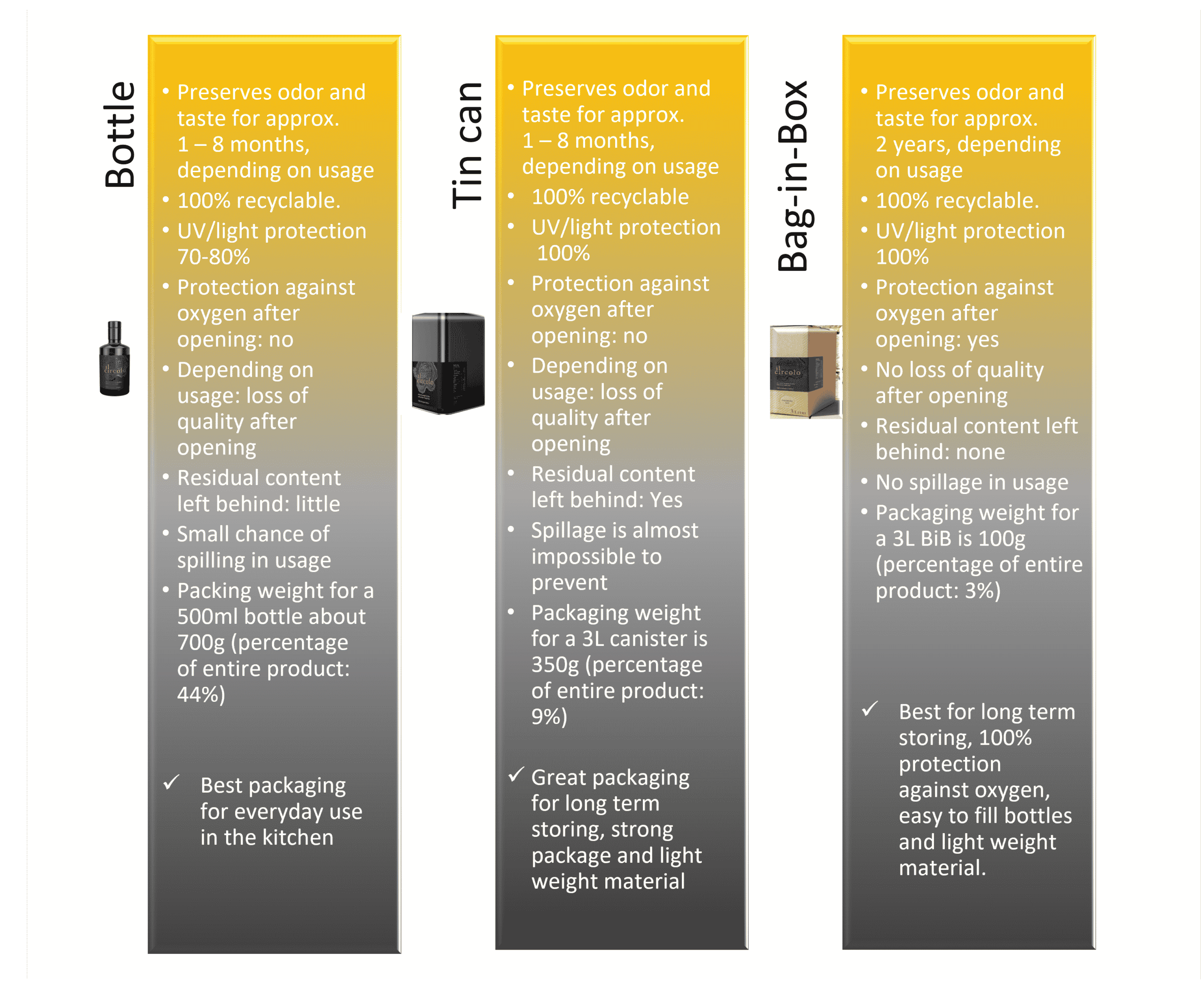

There are good reasons why the bag-in-box is a good alternative for storing olive oil compared to the tin can and glass bottle.

The airtight closure by the tap increases the shelf life and guarantees the preservation of the organoleptic properties. The aroma and freshness of the oil are also preserved. This is due to the good protection of the olive oil from atmospheric oxygen and light or UV radiation in the bag-in-box packaging, which ensures that oxidation processes are avoided. (1)

When decanting from a canister, on the other hand, there is renewed contact with oxygen every time the canister is opened. Olive oil is very susceptible to oxidation by atmospheric oxygen. Even if there is only a little air in the upper part of the canister, the olive oil can oxidise through contact with oxygen and lose its aroma over time. While the olive oil in canisters remains in constant contact with an air cushion on the top of the canister after it is first opened, the bag in the bag-in-box system protects the oil from direct contact with oxygen even after opening and until the last decanting. Research conducted by the Food Chemistry Laboratory at the University of Ioannina in 2019 demonstrated a 50% longer shelf life of olive oil in bag-in-box packaging compared to canisters. (2)

The bag-in-box is significantly more environmentally friendly than other packaging.

The empty packaging is delivered flat, takes up little space and can be easily stored and transported on pallets after filling. This leads to significant savings in logistics costs and CO2 emissions, because the ratio of packaging weight to product volume is very good. For example, one truck transporting 5 litres of Bag-in-Box is equivalent to more than 7 trucks transporting 75 cL glass bottles. At the same time, the Bag-in-Box also takes up little space in storage thanks to its rectangular shape.

In several LCA (life cycle assessment) studies, Bag-in-Box clearly shows the best results, with a carbon footprint eight times lower than glass bottles. The water and energy consumption for the production of Bag-in-Box is relatively low compared to other types of packaging. This is particularly important as the increase in greenhouse gas emissions is the main driver of global warming, leading to sea level rise, mass extinction of species and extreme weather conditions, among other things.

The bag-in-box packaging material consists of an inner bag made of film composite material (usually aluminium/HDPE or polyethylene (PE) in combination with ethylvinyl alcohol (EVOH)), which is protected by an outer carton. The inner bag is fitted with a plastic tap. The cardboard box can be produced CO2-neutral from FSC certified paper. After use, it can be disposed of as waste paper and is then recycled again. After emptying, all that remains with the Bag-in-Box is the plastic bag, which can simply be disposed of via the yellow bag. Unfortunately, it cannot yet be recycled because of the aluminium layer. There are packaging manufacturers who are developing an inner bag for BiB that can be recycled. When these come on the market, recycling can become even more efficient – also depending on the infrastructure for waste collection, separation and recycling in the respective country.

First you open a pre-cut window in the outer box and take out the tap. Sometimes this has to be turned a little straight. With the help of the tap, the olive oil can then be easily and effortlessly filled into a small oil can. The flexible inner bag gradually contracts during filling and prevents air and thus oxygen from getting into the olive oil.

Sources:

We cook with extra virgin olive oil! We have found that olive oil is at its best in simple dishes

The idea of a regenerative food system has been around for quite some time. In simple terms, it is working

Into our 6th year of producing organic extra virgin olive oil, we at il circolo are becoming more and more

il circolo V.O.F.

Tacituslaan 7

3584AP Utrecht

Netherlands

[email protected]

tel: +31 (0)6 42254141

KvK/HRB: 74704257

BTW/MwSt: NL859998502B01

5 euro discount on your next purchase?

Sign up for our newsletter with tasty recipes and interesting background stories about il circolo olive oil and receive a discount code for yourself and your friends (displayed after email confirmation).

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.