4 Reasons to buy olive oil in a Bag-in-Box

The bag-in-box (abbreviated as BiB) has been known as a packaging concept for a long time. The packaging consists of

Il circolo is a small traditional olive oil producer. Our olives are still picked by hand and that is quite labour-intensive. We sometimes get questions about this. Il circolo would like to farm in a regenerative way and this way of harvesting fits well with that. We would like to tell you more about it.

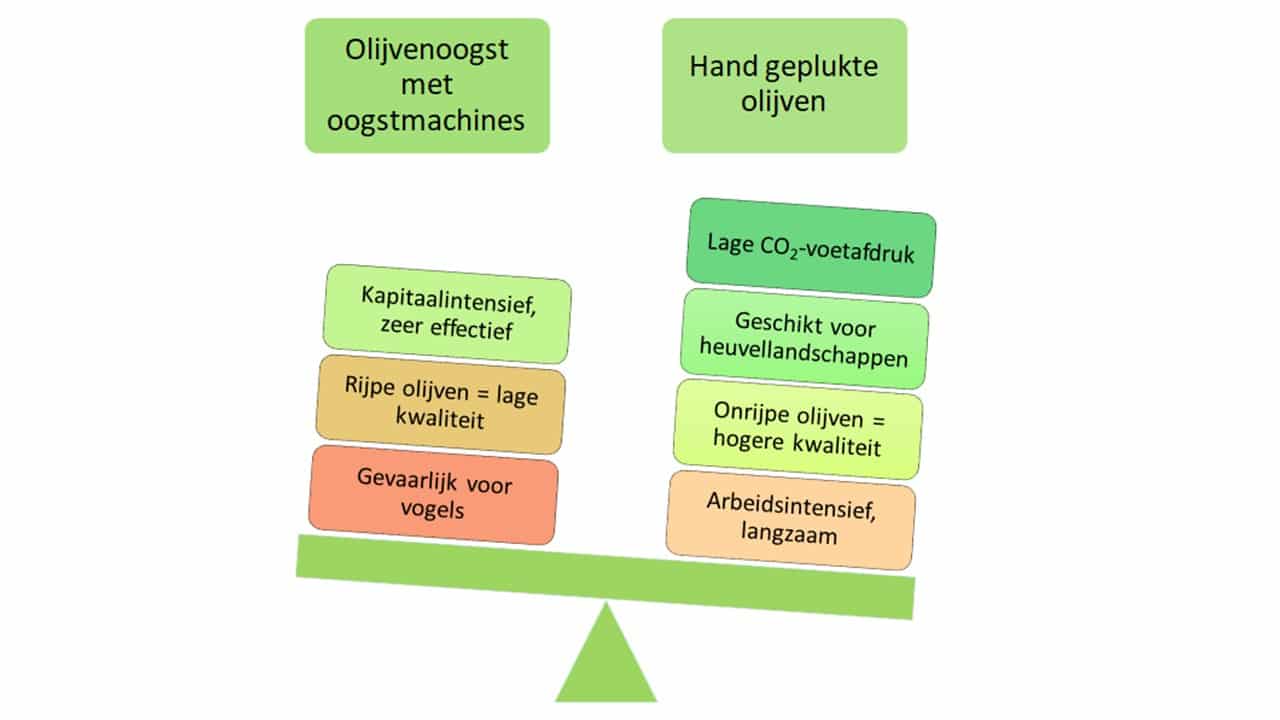

There are two ways to harvest olives: traditionally by hand or mechanically with modern harvesting machines. In Sicily, olives are traditionally combed from the branches by hand, either with sticks or with harvesting rakes.

Nowadays, pneumatic or electric combs or a hand-operated shaking machine are also often used. The olives are “combed off” the tree and collected in large nets under the trees.

Nowadays, pneumatic or electric combs or a hand-operated shaking machine are also often used. The olives are “combed off” the tree and collected in large nets under the trees.

With this harvesting method, small branches and leaves also end up in the nets. The loss of these twigs and leaves is not harmful for the tree. They would be removed anyway during pruning after the harvest. In the past, the twigs and leaves were taken out directly, but nowadays they are filtered out in the modern olive oil mills. Finally, the harvested olives are placed in large bags or baskets and transported to the olive oil mill for further processing. Mechanical olive harvesting involves large harvesting machines. These are large shakers and special pistons used for harvesting. The shaker grips the trunk of the olive tree with a gripper arm and shakes it briefly at a very high frequency. Afterwards, special devices suck up the fallen olives. There are also harvesting machines that combine shaking and suction very efficiently. These work only on young trees and on a flat surface.

With this harvesting method, small branches and leaves also end up in the nets. The loss of these twigs and leaves is not harmful for the tree. They would be removed anyway during pruning after the harvest. In the past, the twigs and leaves were taken out directly, but nowadays they are filtered out in the modern olive oil mills. Finally, the harvested olives are placed in large bags or baskets and transported to the olive oil mill for further processing. Mechanical olive harvesting involves large harvesting machines. These are large shakers and special pistons used for harvesting. The shaker grips the trunk of the olive tree with a gripper arm and shakes it briefly at a very high frequency. Afterwards, special devices suck up the fallen olives. There are also harvesting machines that combine shaking and suction very efficiently. These work only on young trees and on a flat surface. Then there is the so-called ‘log shaker’, which works with an inverted sieve. This has the advantage that it can be used with older trees or for a few large branches and also on less flat land.

Then there is the so-called ‘log shaker’, which works with an inverted sieve. This has the advantage that it can be used with older trees or for a few large branches and also on less flat land.

Harvesting by hand is best for the quality of the olive oil. (1) That way, the olives can be harvested at the optimum time. That is, when they are just barely ripe and before they fall off the branch. It makes little difference whether the olives are picked by hand or by a hand shaker. However, when the olives are beaten out of the tree with a stick, they are often damaged and the fermentation process is accelerated. This fermentation can only be stopped by processing the olives. In practical terms, this means that damaged olives must be processed within a few hours in order to continue to provide top-quality olive oil.

Industrial harvesting machines can only be used when the olives are close to falling off the branch and are actually more than ripe. Some olives are already fermenting at this late stage of the harvest. You could say that with this method, only low quality olive oil can be produced.

Industrial harvesting machines can only be used when the olives are close to falling off the branch and are actually more than ripe. Some olives are already fermenting at this late stage of the harvest. You could say that with this method, only low quality olive oil can be produced.

Harvesting olives by hand is the most labour-intensive – and therefore the most expensive – method. To qualify for the coveted D.O.P. certificate, olive growers must use traditional production methods. To give an idea: In 2019, harvest productivity at il circolo was 1.3 – 2.5 trees per worker per hour. This equates to 20-26 kilos of olives harvested per worker per hour (of which less than 1% were leaves and twigs). Thus, the olive harvest is very expensive and actually makes it unprofitable for Sicilian farmers. Every year, many olive farmers give up, as it is almost impossible to make a living out of olive cultivation. As a result, many Sicilian olive groves are abandoned.

For many traditional olive groves with older trees, the use of modern harvesting machines – such as a log shaker – is difficult because they are designed for standardised use. Thus, the shape of the olive tree determines whether the harvester will work. Deviating shapes – as is more often the case with older trees – the machine cannot cope with. In older olive groves, the trees are usually located on steep slopes and not always in neat rows spread out across the land. This makes the use of harvesting machines more difficult as well as the lack of suitable roads between the pieces of land.

For il circolo, the use of a harvesting machine is not an option. In Sicily, the indigenous olive species, such as Cerasuola, Moresca, Nocellara Etnea and Nocellara del Belice, Biancolilla and Tonda Iblea, prefer to grow on the higher plains of the hilly landscape. These are difficult to traverse for modern harvesting machines. Moreover, in order to obtain a good quality olive oil, the olives must be harvested early, before they are ripe. Unripe olives are light and difficult to detach from the branch. This means that we have to pick our olives by hand. The advantage of this is that the CO2 footprint of our olive oil is much lower, which is better for the environment.

Large-scale olive groves cannot do without special harvesting machines. With these modern machines, one person can harvest up to 10 ha per day with a yield of up to 16 tonnes per hour. Not only does this provide a high harvesting capacity, but also a huge saving in labour costs. What you see is that the harvesting machines determine the layout of the olive grove. There is no room for older trees and growing olives on steep slopes is impossible, because only young olive trees can be harvested in spacious rows on flat ground.

Harvesting at night has the advantage that the colder temperatures at night cause the olives to ferment less quickly than during the day. This is positive for the quality of the olive oil. A major disadvantage of harvesting at night is that birds get confused by bright lights and loud noises, so they do not flee but stay in the tree. Birds that are sucked up by the harvesting machine usually do not survive.

The method of harvesting – by machine or by hand – explains the price difference between olive oil from a large-scale producer (often found in supermarkets) and that from small, traditional olive oil producers, which is more exclusive.

The method of harvesting – by machine or by hand – explains the price difference between olive oil from a large-scale producer (often found in supermarkets) and that from small, traditional olive oil producers, which is more exclusive.

(1) Saglam, C., Tuna, Y. T., Gecgel, U., & Atar, E. S. (2014). Effects of Olive Harvesting Methods on Oil Quality. APCBEE procedia, 8, 334-342.

The bag-in-box (abbreviated as BiB) has been known as a packaging concept for a long time. The packaging consists of

Environment, climate, targeted supports, and flexibility. The new Common Agricultural Policy (CAP) of the European Union (EU) was adopted last

Into our 6th year of producing organic extra virgin olive oil, we at il circolo are becoming more and more

il circolo V.O.F.

Tacituslaan 7

3584AP Utrecht

Netherlands

[email protected]

tel: +31 (0)6 42254141

KvK/HRB: 74704257

BTW/MwSt: NL859998502B01

5 euro discount on your next purchase?

Sign up for our newsletter with tasty recipes and interesting background stories about il circolo olive oil and receive a discount code for yourself and your friends (displayed after email confirmation).

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.